Composting Is A Process That Benefits Local Farmers

MacFarlane Pheasants has always composted used bedding and bird droppings. We create windrows that are about 4ft wide by 4ft tall and can be 1500ft long. This is where our “bedding pack” is hauled weekly. It takes about a year of turning the compost by machine to create the breakdown necessary to turn it into nutrient-rich compost. Here’s what the compost machine and mother-nature get done:

▪ Removes carbon dioxide and replaces it with oxygen to allow for the breakdown of organic matter

▪ Manages temperature by removing excess heat and allows the wind-rows to continue the breakdown of organic matter into compost

▪ Mixes without pulverizing–the turning process must mix the material exposing particle surfaces to moisture and microbes without turning the material to dust.

▪ The compost turner thoroughly mixes wind-row materials without pulverizing the humus crumb structure that develops during the build-up phase of the composting process

▪ Allows a one-man operation with operator control from the cab

▪ Mixes and blends composted materials by moving the perimeter materials to the center and center materials to the outside of the wind-rows.

Local farmers pick up the compost that has been reduced in size by about two-thirds in the composting process. This makes it much cheaper to haul away. Farmers who have crops but do not have livestock like to bring in this organic fertilizer rather than purchase fertilizer. Though farmers haul our compost at their own expense, our reduction in the size of the nutrient-rich product helps hold their costs down.

It is a win/win situation for MacFarlane Pheasants and our local farmers. If you would like to know more about composting, Ryan George can be emailed at r.george@pheasant.com.

Related Posts

DuPont Financial Analysis Model

Read Post

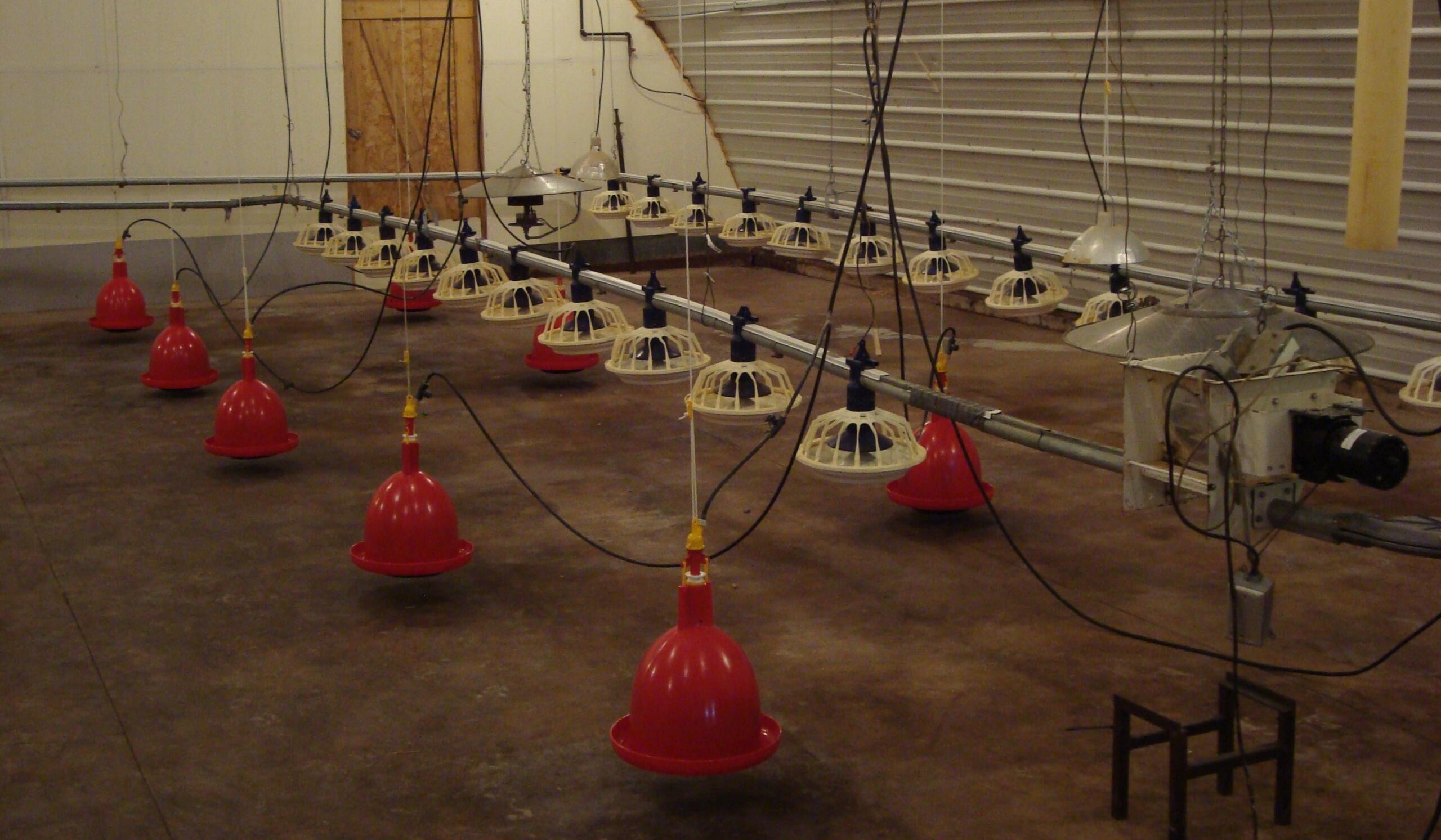

6 Feed and Water Procedures to Keep MacFarlane Pheasants Healthy

Read Post

Advice on what protein % feed to use for your pheasants.

Read Post

All Pheasant Feed Is Not Created Equal

Read Post

A Pheasant Farm’s Most Wanted List

Read Post

Bill MacFarlane Featured In Mother Earth News!

Read Post

Birds For Mounting

Read Post

Can Goats Be Helpful on a Pheasant Farm?

Read Post

Take Advantage of These Free Resources

As the biggest game bird farm in the United States, we want to share our experience with you. Download our free resources below and get started.